3D Printing in Aerospace and Defence Industry: Engineering the Next Frontier

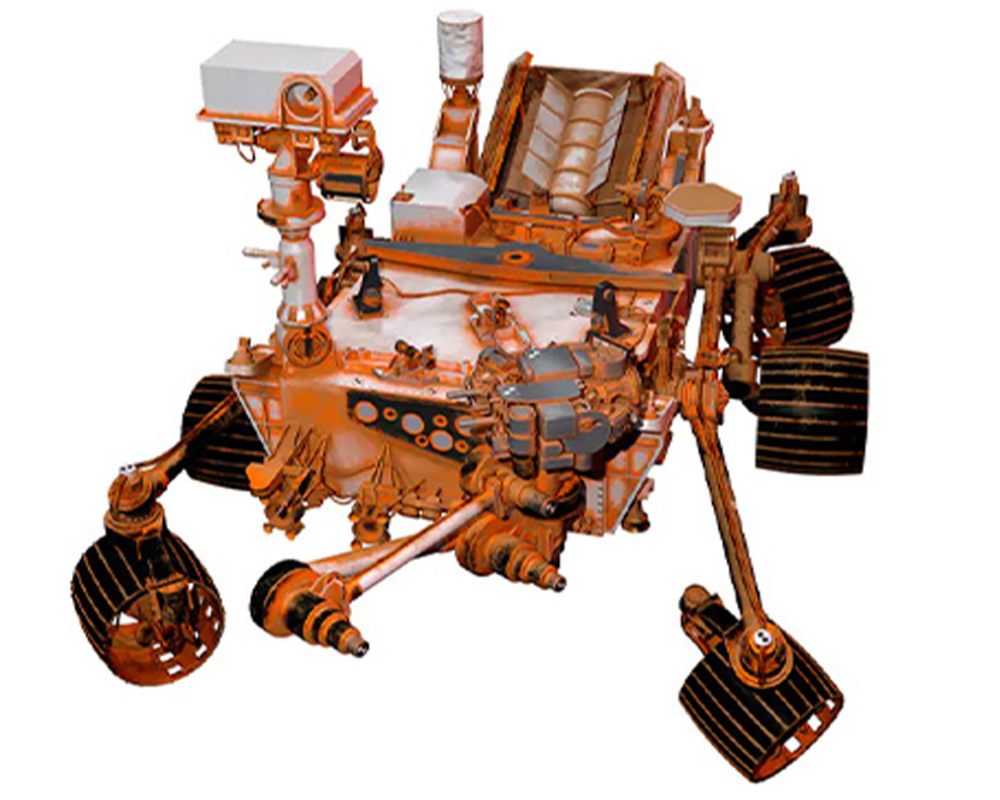

The latest tech brings in the advantage of creating something new and exclusive. Bring in the change in industry 3D printing in aerospace industry has hype because of its creativity in showing how it works. We are currently seeing a typical pattern: with each breakthrough, industry players withdraw from the industry to focus on the new momentum. Even if we know what to expect next, the work behind the scenes is astounding, and it’s all geared toward gaining a competitive advantage. As a result, it is not surprising that 36% plan to invest in additive manufacturing within the next five years. This figure excludes early adopters of additive manufacturing technologies in the market sector.

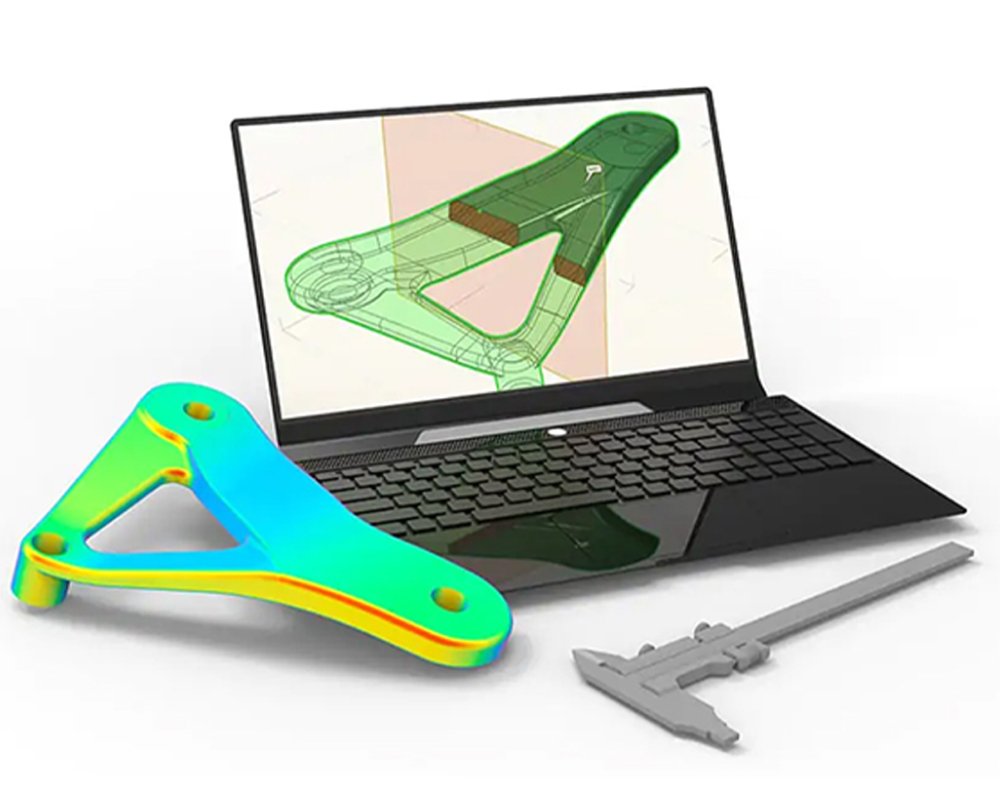

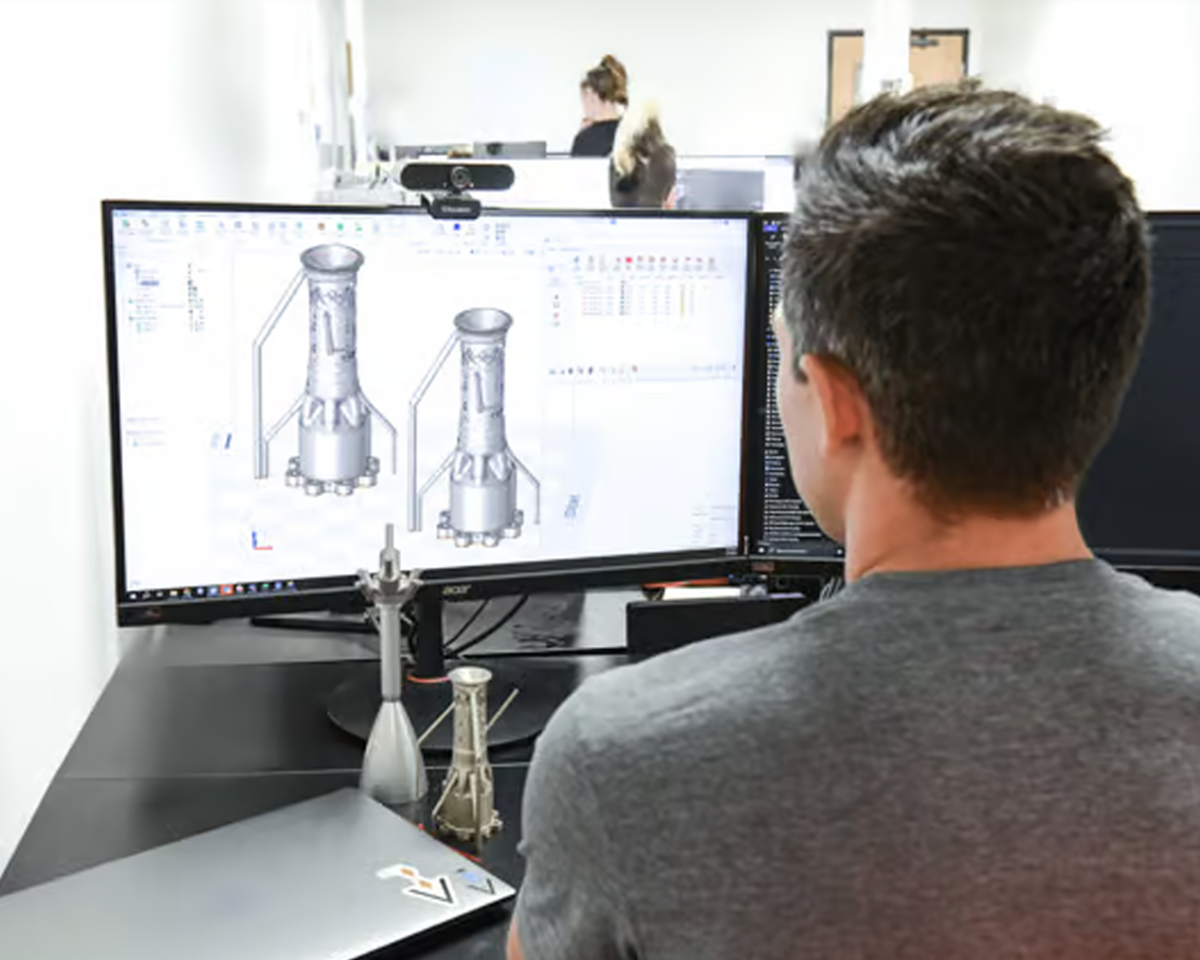

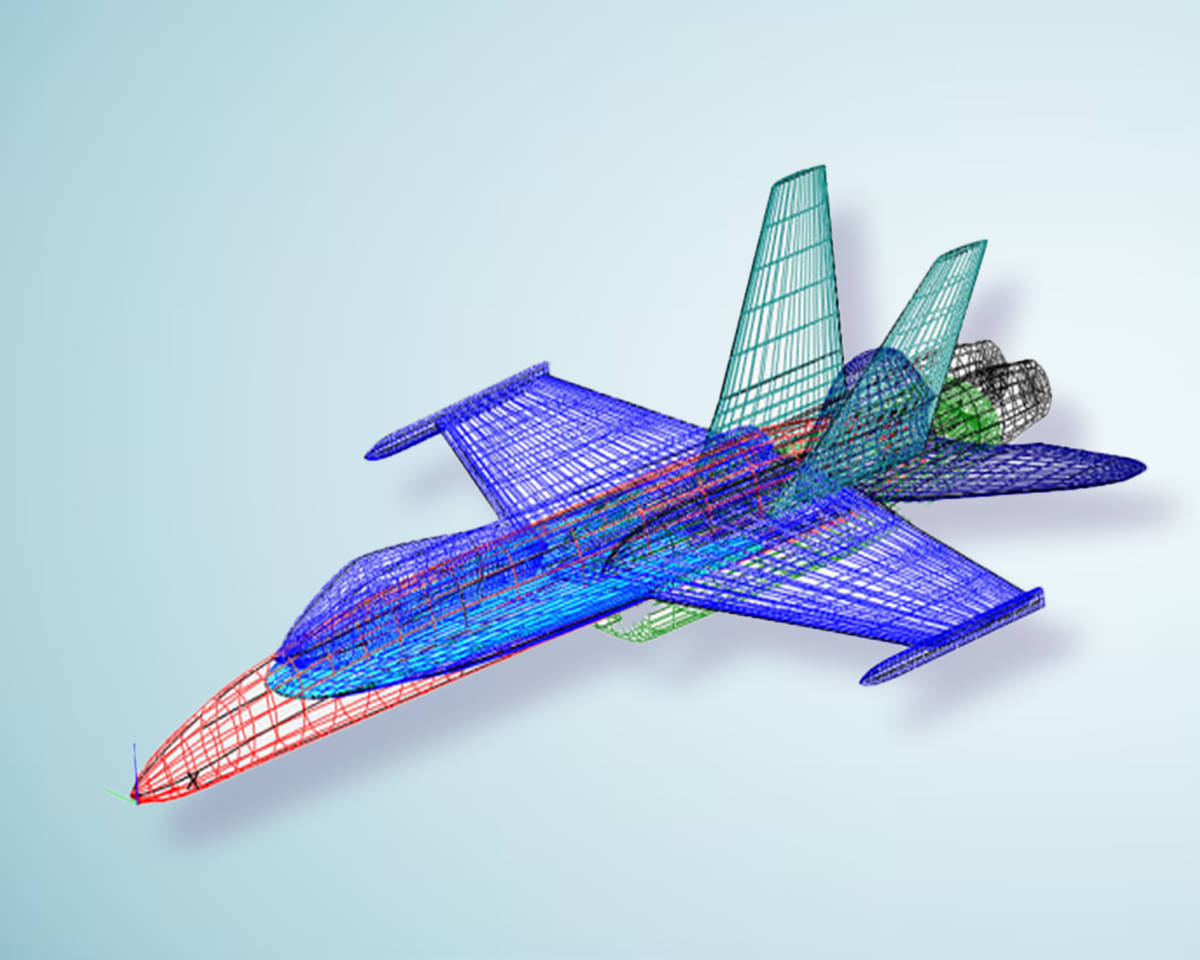

Aircraft manufacturers benefit from Arc India’s competence in large-scale additive manufacturing, which allows for the creation of complicated components with shorter lead times and costs. Arc India enables businesses to improve supply chains, increase production flexibility, and meet the demands of modern aerospace markets through strategic partnerships along with customized solutions.

Arc India is leading the industry toward more eco-friendly and sustainable practices, in line with worldwide initiatives to minimize carbon emissions and environmental impact.