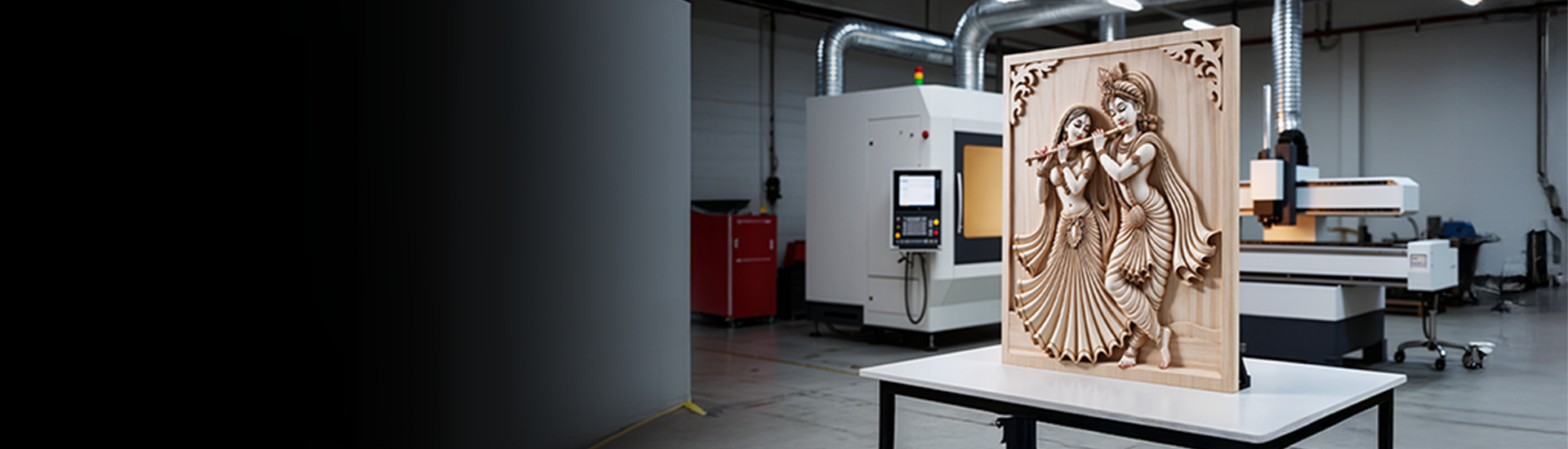

The Art Of The CNC Wood Curving. The Soul Of The Wood

The latest CNC Wood Carving technology from ARC India combines advanced machine technology to create stunning pieces of artwork that display extraordinary detail through careful design of their curves and emphasis on natural beauty and craftsmanship. ARC India offers a complete solution for wood carving with advanced, high-precision machinery. Now serving the vibrant hub of Bangalore, we provide the ideal tools for both creative freelancers and established wood-based businesses looking to elevate their craftsmanship. Our innovative machinery ensures precise cutting, engraving, polishing, and fabrication at reasonable prices. Designed for advertising and woodworking, we deliver quality, efficiency, and reliable results.

The finish and feel of the timber, depth and warmth, along with the dissimilarities of timber’s character, are taken into consideration when designing this beautiful artwork. It’s charged per Sq. Inch 4. And wood thickness of up to 40 mm, and it is suitable for all types of industries, ideal premium wooden gifting solutions.

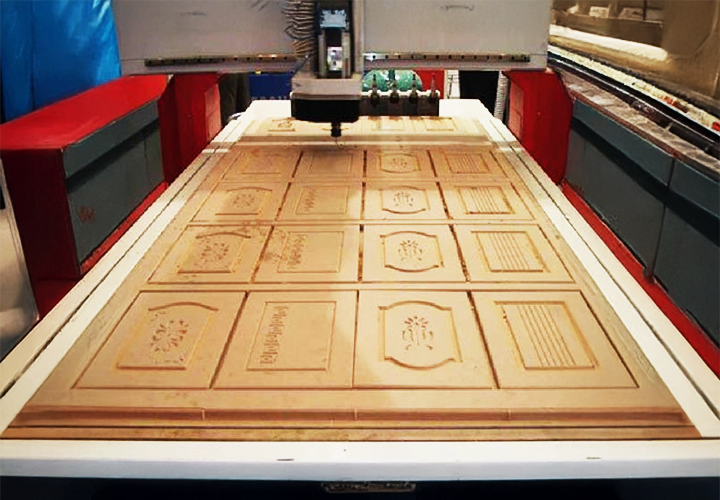

Heavy-duty, speedy, multi-functional CNC wood carving machine in Bangalore for processing complicated work pieces with 8/4 width. 360° rotary for engraving body, Buddha statue, sculpture, crafts and furniture. Anyone can use our fine machine for their business requirement, experience the latest techniques that we are providing you.

How It Works

Digital Design

The design is converted from its concept into a digitally generated blueprint to the highest standard of accuracy(e.g., Fusion 360, VCarve Pro or Aspire).

Intelligence Mapping

Producing optimised toolpaths through defining the appropriate movements and logic that achieve a perfect result.

Precision Execution

Optimized toolpaths to life through the creation of complex carvings, three-dimensional , sculpted forms and detailed contours.

Types of CNC Wood Carving Machines

CNC Routers

CNC Routers are one of the main types of machines that we use here at ARC India to create signs, furniture, cabinets, wall decorations and intricate wood carvings by way of rotating cutting tools.

CNC Laser Cutters/Engravers

CNC Laser Cutters / Engravers utilize laser technology to allow finely detailed engraving, fine details, branding work and very precise cutting of thin wood sheets.

CNC Milling Machines

CNC Milling Machines are heavy-duty pieces of equipment that are used primarily by ARC India to carve high-density hardwoods and thick wood sections with an extremely precise and durable finish.

Materials Used

CNC routers can work with many types of wood:

Softwoods (pine, cedar)

Hardwoods (oak, walnut, maple)

Plywood

MDF (pine, cedar)

Bamboo

Common Uses

What People Use CNC Wood Carving For –

Wooden signboards in 2D and with exact cuts and smooth finishes

Engravings that are very detailed for decoration, branding, and art purposes

Parts for furniture that have the same design and exact measurements

Cabinet doors and joinery work with neat edges and patterns

Guitar and God Idols' bodies that can be shaped in a controlled way

Relief sculptures that show depth and fine details

Wooden prototypes and molds for testing and developing designs

Inlay work that is very precise for decorative wooden surfaces

Essential Tools and Bits

CNC wood carving uses different router bits, such as:

End mills (flat-bottom cuts)

Ball-nose bits (carving)

V-bits (engraving and sign making)

Compression bits (clean plywood cuts)

Surfacing bits (flattening boards)

Advantages

Wood Carving options:

Decorative wall frames and wall art, to architectural pieces and beautifully detailed carved wooden doors.

Precision and Attention to Detail

Creative pieces are hand-made, in contrast to mass-produced assembly line products.

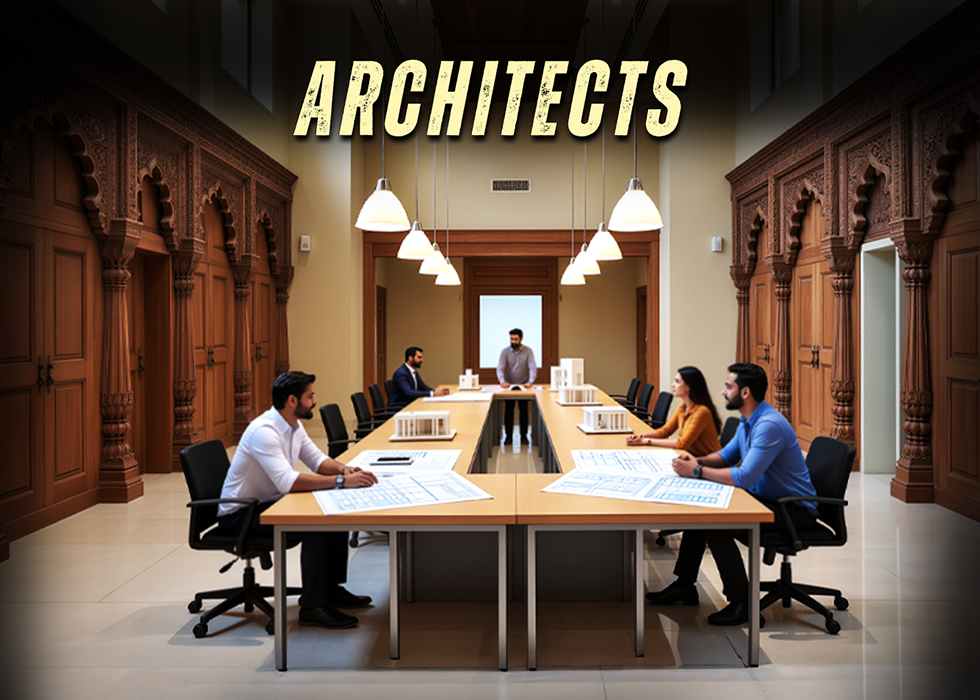

Range of Available Services for Professionals

Available services for Interior Designers and Architects.

Fine Quality of Raw Materials

Utilizes only the finest quality, most durable and visually appealing raw materials.

Unique, Custom Creative Options

Providing a complete range of choices from Decorative Wall Art to Custom Designed Architectural Entry and Interior Doors.

High-Tech Precision

Combining Old World Charm with Digital Laser Accuracy.

Who Can Connect With Us & Grab Opportunities?

Wood carving is the latest opportunity for all the freelancers, architects, decor retailers or interior designers out there, a scope to work on bigger projects and get them done. ARC India is introducing CNC wood carving, allowing them to use it for their woodworking with a better finish and stress-free production in Bangalore location. Consistency stays intact with quality. With an advanced CNC router machine, we let you do your carving with ease.

- Wood Carving Freelancers: Fast, precise CNC wood carving that helps freelancers deliver perfect work on time, every time.

- Architects: Turn creative concepts into finely carved wooden elements with CNC accuracy.

- Interior Designers : Add premium carved wood textures to interiors with flawless machine precision.

- Decor Retailers: High-quality carved wood products that attract customers and boost showroom appeal.

Connect with us at: 95355 99300

Review Date

Full Text

Testimonials

Our customers love us, read what they have to say about us

Frequently Asked Questions

CNC Wood Carving is a method of machining wood using computer – controlled machinery and specialized software. At ARC India, we have CNC Wood Carving Machines that will allow us to create the most detailed, intricate designs on wood substrates as possible.

We have many different types and styles of materials. Examples of Materials we frequently work with are: MDF (Medium Density Fiberboard), Plywood, Teak Wood, Pine Wood, Hardwood, and Engineered Woods. Your Choice of Material Will Depend on what fabric or material you are using and Your Budget and Application Routine.

Interior Design, Architectural, Furniture Manufacturing, Retail Fit Out, Hospitality and All Custom Decorative Applications.

At ARC India, we use the best technologies that provide us with the best results, and each carving that is done results in accurate shapes and sizes. Wood options you can get like teak, oak, mahogany, walnut and more. If you have any preferences, then get in touch with us for more information.

Carving by hand definitely has some unique features, but traditional ways slow down the entire process. We deliver on time and with quality results, and CNC carving is much faster; it makes perfect copies of complicated designs and can produce multiple pieces.

Yes indeed, you can provide us with your own designs that you want for your requirement, and we are here to fix it and deliver on time. Our team uses the best machinery to get it done, and the latest technology adds extra fusion to it.

Customers utilize ARC’s CNC services for CNC carving of wooden idolatry (deities), specialty architectural wall panels, decorative doors, intricate furniture parts, signage, and intricate decorative sculptures designed for use in designer or high-end Interior spaces.

Timelines can vary from a few hours for simple 2D engravings to weeks for detailed sculptures or large architectural panels, depending on the complexity of a specific project or its material composition.

No, our CNC capability achieves clean and precise cuts that preserve the natural warmth and grain pattern of the wood while highlighting the inherent beauty of the raw material through the way we create tool paths and use cutting too

Yes, all of our CNC wood carving services are available throughout all Bangalore pin code areas, supporting interior designers, architects and carpenters with reliable manufacturing and fast turnaround times.

The ability to provide greater accuracy and repeatability over traditional hand carving is the key advantage of CNC wood carving. With a CNC machine, the depth is uniform, edges are clean, and the same on every piece created, which saves time and waste material.

CNC carving provides identical output at scale, providing precision and repeatability. Thus, CNC carving is ideal for large architectural projects to produce consistent and identical results on items like building facades, space feature walls, retail interiors, and branded spaces.

Carpenters can engage us to create their CNC wood carved projects. We take care of custom designs on large volumes, create items as soon as possible and concentrate on the installation and finishing parts of the project.

ARC India has the equipment and training necessary to create the highest quality of CNC carving available. Along with our inventory of custom CNC machines, we have experienced staff members who have developed their expertise over the years. They can also offer guidance for designing your CNC carved product (no matter if you are looking for a custom fireplace surround or architectural element).

Get Free Consultation & Quotation

Fill up the details below

Get Your Download Now

Fill up the details below