From Resin to Reality: Mastering SLA 3D Printing Technology

Stereolithography (SLA) 3D printing is one of the most precise and versatile additive manufacturing technologies available. Praised for producing high-detail parts with a smooth finish, SLA finds widespread application in industries like prototyping, dentistry, jewelry, and engineering. This blog gives a thorough explanation of the way SLA 3D printing works, its basic parts, the process of printing, and its applications, giving an overall overview of this cutting-edge technology.

What is SLA 3D Printing?

SLA, or stereolithography, is a 3D printing process that employs a laser to cure liquid resin layer by layer into solid components. Developed in the 1980s by 3D Systems founder Chuck Hull, SLA was the first commercially successful 3D printing technology. It continues to be a staple of additive manufacturing today because it can produce complex, high-resolution components with high accuracy.

Unlike filament-based 3D printing (e.g., FDM), SLA uses photopolymerization, a chemical reaction initiated by ultraviolet (UV) light in a liquid resin, which causes it to solidify. This allows SLA printers to print with greater detail and smoother surfaces, suitable for precision applications.

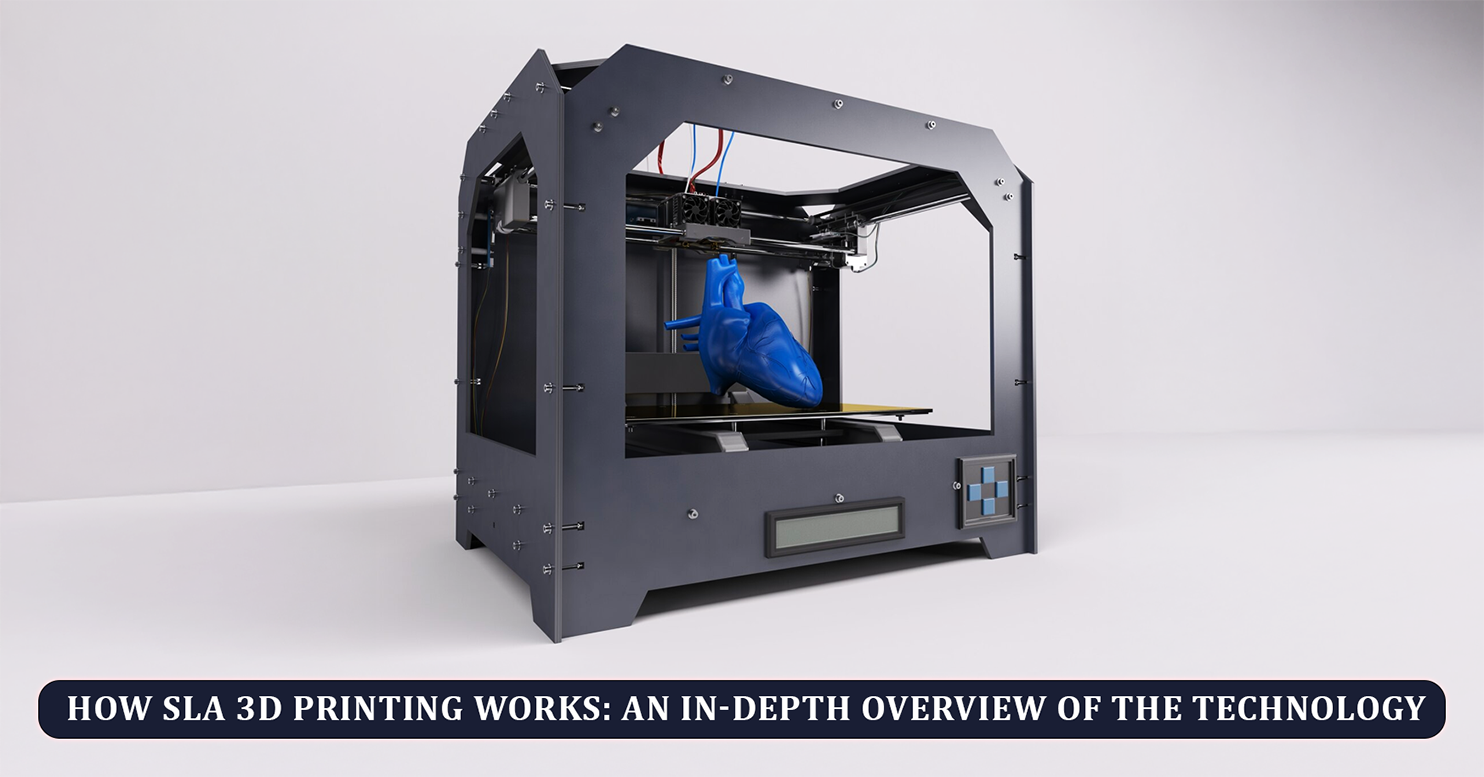

Major Components of an SLA 3D Printer

In order to learn how SLA works, one must learn about the major components of an SLA 3D printer:

Resin Tank:

A liquid reservoir of photopolymer resin which is pumped into the printer. It has a transparent bottom (typically fabricated using some form of material such as FEP film) from which the laser light will exit.

Laser:

The main hardware in the SLA system is a UV laser. It will cure the resin selectively by sucking in the cross-section of every layer.

Galvanometers:

Mirrors that guide the laser beam with high accuracy along the surface of the resin, as instructed by the software of the printer.

Build Platform:

A platform that moves down into the vat of resin to begin printing and slowly raises up as each layer hardens to build the final product.

Control System:

The computer software of the printer reads the 3D model (most often in STL or OBJ) and translates it into a laser and build platform command.

SLA Printing Process

SLA printing is some process with some steps involved, every single one of which plays an essential role to develop a good-quality part. The following is a step-by-step guide:

1. Design and Slicing

The procedure begins from a CAD software-based 3D model. The computer file is imported into slicing software, which decomposes the model into layers (typically 25–100 microns thick). The software also generates a command set for the printer, e.g., the laser path per layer.

2. Printer Setup

The resin tank is filled with liquid photopolymer resin, and the build platform is placed just below the resin surface, and there is an incredibly thin resin layer between it and the clear tank bottom.

3. Layer-by-Layer Curing

The UV laser, galvanometer-controlled, inscribes the cross-section of the first layer onto the resin. The laser beam cures the resin immediately in the area that is exposed to it. Once a layer is complete, the build platform lifts a little (one layer thickness) and fresh resin drips underneath it.

4. Peeling and Recoating

To prevent the cured resin from sticking to the bottom of the tank, most SLA printers incorporate a peeling action, where the tank is tilted or the platform vibrated to peel off the part. The new resin recoats the building area again, ready for the next layer.

5. Repeating the Process

The cycle of curing, lifting, and recoating is then repeated on each layer until the object is finished. It may take hours depending on how complex and how large the part is.

6. Post-Processing

After printing, the build plate is taken off, and the object is retrieved from the resin container. The object remains with a layer of uncured resin on its surface, so it is washed in a solvent (such as isopropyl alcohol) to strip off excess resin. The object is then put into a UV curing oven to harden completely, providing maximum strength and stability.

Types of SLA Technologies

While traditional SLA uses a beam of light from a laser to cure resin a point at a time in small increments, modifications of the process have been made to speed it up and increase efficiency:

Digital Light Processing (DLP):

Rather than with a laser, DLP makes use of a projector that pulses a whole layer’s image upon the resin in one step, accelerating the procedure.

Masked SLA (MSLA):

Just like DLP, MSLA also masks the UV light with an LCD display and cures layers at once. MSLA printers are also less costly and consumer-grade.

Advantages of SLA 3D Printing

Custom SLA has an abundance of advantages that make it the go-to choice in the majority of applications:

High Resolution:

SLA can create layer thicknesses as low as below 25 microns, and the parts can be of excellent detail and surface finish.

Material Flexibility:

Resins come in numerous different formulas such as standard, flexible, rugged, and biocompatible resins, providing the user with a number of different requirements to fulfill.

Accuracy:

SLA’s high accuracy is what makes it particularly suitable for its application in dental models, jewelry molds, and functional prototypes.

Shortcomings of SLA

Behind all the SLA strengths are the following few drawbacks:

Cost: The SLA printer and associated resins are more expensive than the FDM variant.

Post-Processing: Clean-up and curing are complex and involve sophisticated workflow.

Material Handling: Resins are sticky, toxic, and must be stored and disposed of in accordance with procedure.

Applications of SLA 3D Printing

SLA’s accuracy and versatility make it indispensable across industries:

Prototyping:

SLA is employed by designers to produce detailed prototype models for product development.

Dentistry:

SLA prints precise dental models, aligners, and surgical guides.

Jewelry:

Jewelers employ SLA to produce intricate casting patterns for custom designs.

Medical:

Biocompatible resins allow for the creation of custom prosthetics and implants.

Engineering:

SLA is applied to functional parts and complex assemblies with high tolerances.

The Future of SLA 3D Printing

As SLA technology evolves, we’re seeing advancements in speed, affordability, and material options. New resins with enhanced properties, like heat resistance or biodegradability, are expanding SLA’s applications. Additionally, improvements in DLP and MSLA technologies are making high-resolution printing more accessible to hobbyists and small businesses.

Conclusion

Custom SLA 3D printing is a robust technology with the combination of precision, versatility, and reliability. SLA creates parts with unparalleled surface quality and resolution, with liquid resin cured layer by layer by UV laser. It might need to be treated extremely gently and possibly require post-processing, but all its advantages for which industry players sweat make it the top choice of experts in the field. With developments propelling the industry further, SLA is destined to play a much greater role in additive manufacturing years ahead. So get going with ARC India as your service provider that helps you to shape your business branding needs. Get in touch with us to know more.